Chocolate Granulator utilizes the characteristic that the melting point of the material is below 300 ℃. Based on the viscosity range of the material in the molten state, a special fabric device is used to evenly distribute the molten liquid on the steel strip that moves uniformly below it. Under the cooling effect of the continuous spray device set below the steel strip, the material is cooled, solidified, and packaged during transportation, thus achieving the purpose of granulation and forming.

This product is a new type of (melting) forming granulator. The work changes from liquid to solid through transportation and cooling, and materials with a melting point range of 50 ℃ to 300 ℃ can be granulated and formed. No dust, improved production environment; And it has certain economic value (energy-saving, packaging container economy), fast product replacement, aesthetically pleasing granular products, uniform nearly hemispherical granular, and no thermal stress; Granular products are easy to package, transport, and store, as well as convenient for users to measure, mix, or remelt, and can be produced continuously. From feeding to packaging, it reduces physical labor, has stepless speed regulation, adjustable flow rate, and easy operation. Widely used in industries such as petroleum and fine chemicals. One machine can be used for making strips, pieces, and sheets; Toxic materials can be sealed in a lump.

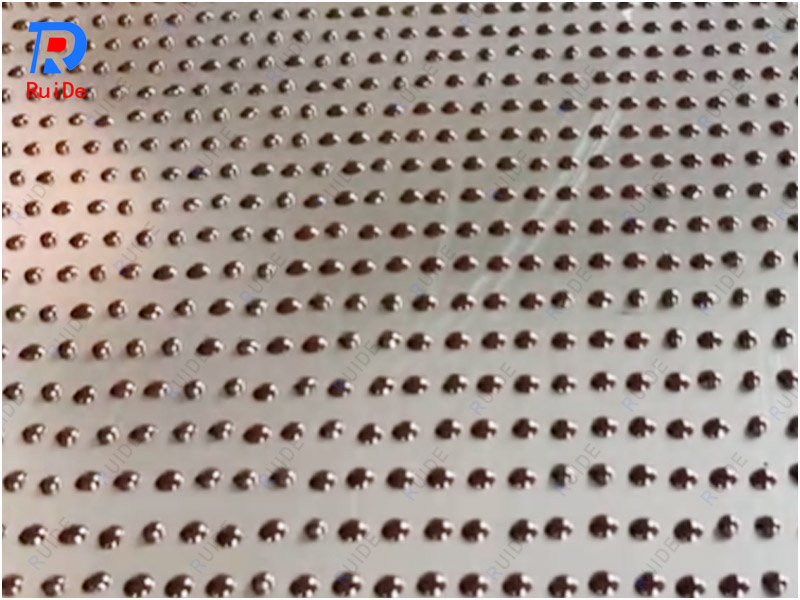

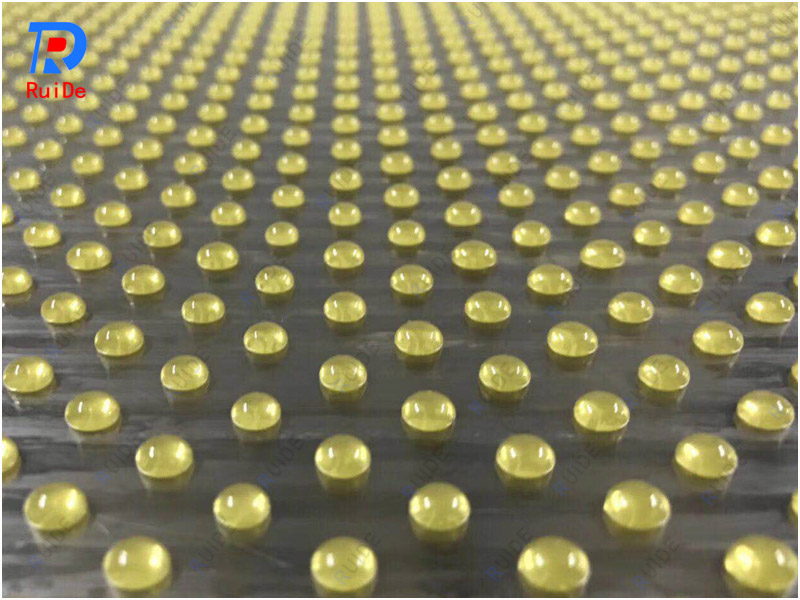

The molten material in the material tank is pumped out by the material pump and sent to the fabric feeder through a filter. The outer drum rotates around the stator. When the pointed mouth on the outer drum passes through the bottom of the stator, a certain amount of material will be sprayed out through the pointed hole on the outer drum and drip onto the upper surface of the cooling steel strip below. After being transported by the steel strip and cooled by the cooling water, it is cooled into solid particles. The solidified particles are scraped off by the scraper at the tail of the steel strip cooling machine and transported to the packaging machine by the conveyor belt.

The cooling of the material from the fabric dispenser to the product discharge end is roughly divided into three parts

1. Pre cooling process: When droplets are dropped from the fabric dispenser, they are in a high-temperature liquid state and cooled from the high-temperature liquid state to the melting point temperature of the liquid state;

2. Solidification stage: Liquid droplets are transformed from liquid to solid, and the material releases a significant amount of heat during this process, known as solidification heat. The temperature of the material itself remains constant;

3. Material cooling process: During this process, the temperature of the material decreases from its melting point to the temperature required for product packaging;

Based on the total time required for material cooling in the three stages mentioned above, the residence time of the material on the steel strip, and the user's requirements for production capacity, the performance parameters and specifications of the equipment can be determined.

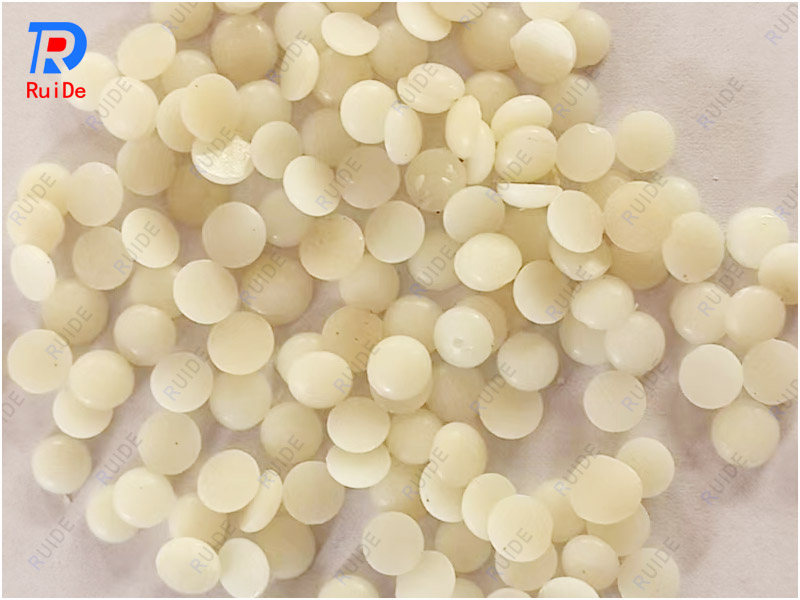

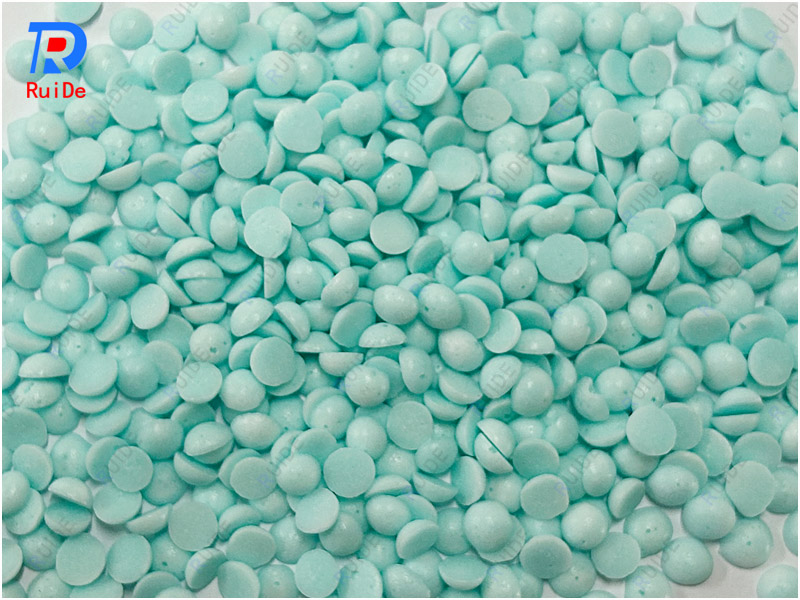

This product is a new type of (melting) forming granulator. The molten liquid is rapidly solidified and formed by using thin steel strip heat transfer and atomized spray cooling, and a single machine rotating shell is adopted. Therefore, it is easy to maintain, has minimal wear and tear, and has high productivity. Quick loading, unloading, and replacement of products. Moreover, the synchronous operation of the mold forming machine and steel strip enables high-speed production of uniform ingots, improving productivity and increasing production profits. And it can eliminate dust, improve the environment, and significantly expand the viscosity range. This product is an economical and reliable production process that can process particles with a diameter of 4-12mm. These products are very uniform, in the form of hemispheres, strips, and flakes, stable, stress free, and of high purity and quality. Due to the built-in filtering and blocking device of the equipment, it operates more reliably.

Structure (1):

Select the conveying speed and machine head speed based on the melting point (solidification point), material temperature viscosity, and cooling effect of the processed product to avoid affecting production capacity and granular quality.

The machine transforms from liquid to solid granules mainly through granulation die, using a rotary steel strip for continuous granulation, and is cooled and shaped by spraying water.

Structure (2):

The machine is mainly composed of a feeding die granulation forming head, a cooling conveyor stainless steel belt and pulley, a spray cooling system, a transmission system, an insulation device, a frame, a scraper, etc. The feeding die granulation machine head is mainly composed of a machine head mold sleeve and a machine head core shaft. The spray cooling system mainly consists of nozzles, water tanks, etc. The transmission system mainly consists of a gearbox (reducer), a speed regulating motor, etc.

1. Reduce dust and improve operating environment; Continuous operation to improve production efficiency; Full particles, beautiful appearance, and increased product value. The particle shape and uniform particle size are beneficial for transportation, packaging, and use, as well as for improving the operating conditions and environment during production and use, enhancing product quality and competitiveness.

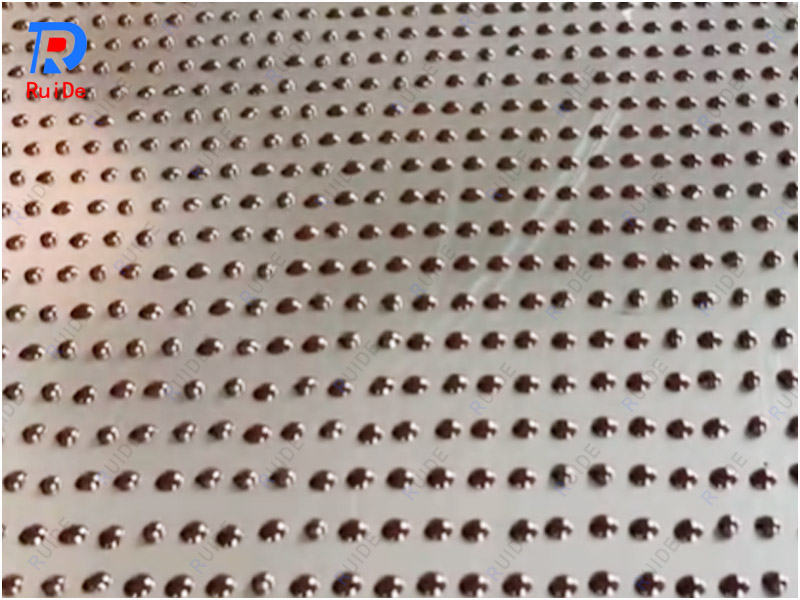

2. By using thin steel strips for heat transfer and atomizing spray for forced cooling, the hot melt material is rapidly condensed and solidified, resulting in a significant improvement in production efficiency. The reversing bending of the steel strip at the discharge end causes separation between the solidified material and the bonding surface of the steel strip, resulting in minimal dust during discharge and complete protection of particle shape.

3. The distributor and steel strip are both driven by variable frequency drive devices, which can be infinitely adjusted and controlled according to production capacity and material characteristics.

4. By using an intelligent temperature controller to distribute and control the temperature at each point, the stability of material temperature and characteristics is ensured, and the quality of granulation is reliably guaranteed.

5. The reversing bending of the steel strip unloading end makes the bonding surface between the solidified particles and the steel strip easy to peel off, resulting in minimal dust during unloading, protecting the particle shape, and reducing the impurity content brought into the product during scraping.

6. By adopting segmented cooling, the cooling temperature of each section can be selected based on the condensation and solidification characteristics of the material, which is extremely advantageous for achieving rapid cooling and solidification of special materials.

7. The steel strip cooling granulator adopts a detachable combination structure in its structure, and the equipment specifications can be selected according to the material characteristics and production capacity, which is conducive to the transportation and installation of large-sized devices.

This product is suitable for various materials with melting points (or softening points) between 50 ℃ and 300 ℃ that require granulation, as well as materials with "supercooling crystallization" characteristics.

Mainly used in various industries such as petroleum, chemical, pharmaceutical, energy, construction, smelting, pesticides, food, new materials, biotechnology, etc. This type of device can also be widely used for rapid cooling and cooling processes of powdered and paste like viscous materials, such as paraffin, resin, sulfur, asphalt, fragrance beads, rosin, rubber additives, plastic additives, curing agents, hot sols, chocolate, petroleum resins, phenolic resins, rosin resins, polyamide resins, C5 resins, C9 resins, polyester resins, epoxy resins, edible waxes, casting waxes, hydrogenated palm wax, jewelry wax, beeswax, microcrystalline wax, cosmetic wax, medical paraffin, PE wax, polyethylene wax, petroleum asphalt, L-lactide, polysulfone, urea, crown ethers, flame retardants, antioxidants, printing and dyeing auxiliaries, sodium cocoyl hydroxyethyl sulfonate, N-methylacrylamide, 4,4 '- difluorobiphenyl Ketone, BHET, TGIC, Tylenol PVC stabilizer, maleic anhydride, partial anhydride, p-nitrochlorobenzene, stearate, fatty acid, aluminum sulfate, caprolactam, phosphate flame retardant, calcium chloride, m-phenylenediamine, catechol, sodium hydrosulfide, stearic acid, alkali sulfide, emulsion explosive matrix, crystal matrix, sodium fluorosilicate and other materials.

The material must be filtered for solid impurities and must not enter the granulation head, otherwise it will cause wear or blockage of the head, affecting the quality of granulation.

The temperature control should be determined based on the melting point temperature, and the insulation requirement is that the temperature change should not exceed ± 3 ℃. The cooling system should be equipped with a filter screen, and the temperature of the cooling water is generally between 5 ℃ -25 ℃ (low water temperature, fast forming, good granulation, high output).

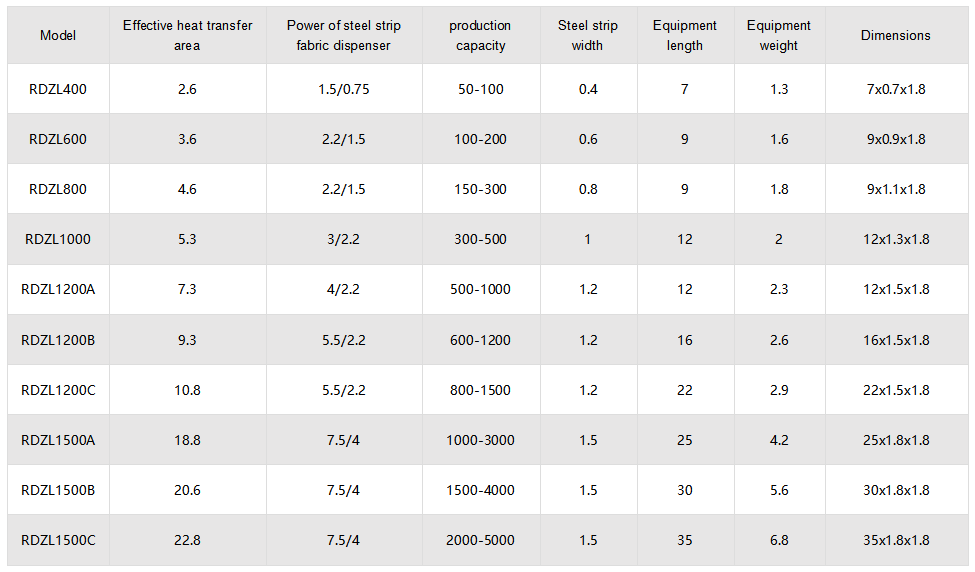

1. Production capacity depends on the performance of specific materials

2. The particle size is determined according to user requirements

3. The above models are for reference only

4. Depending on product performance and body length

In addition, our company also has a product testing center where users can carry materials to conduct product granulation and forming tests on the granulator. We also provide users with services such as steel strip, steel strip welding, V-strip bonding, granulator feeder, granulator spare parts, and maintenance and renovation.

Previous:Fragrant Bead Granulator

Next:none!