The RDSZ series rotary flash dryer is a new type of drying equipment developed by our company based on the introduction and absorption of foreign technology. This machine has advanced technology, reasonable design, compact structure, wide applicability, high production capacity, good product quality, high efficiency and energy saving. It can dry, crush and screen in one device, eliminating environmental pollution, and achieving international performance. The flash dryer has the original bearing induction cooling (water cooling), which is designed to be connected with an oil pump to lubricate and cool the bearings. The sealing device has excellent performance. The main shaft design adopts a semi ring type, and the motor uses a speed regulating motor, which has smooth transmission, low noise, and a service life 10 times that of similar products.

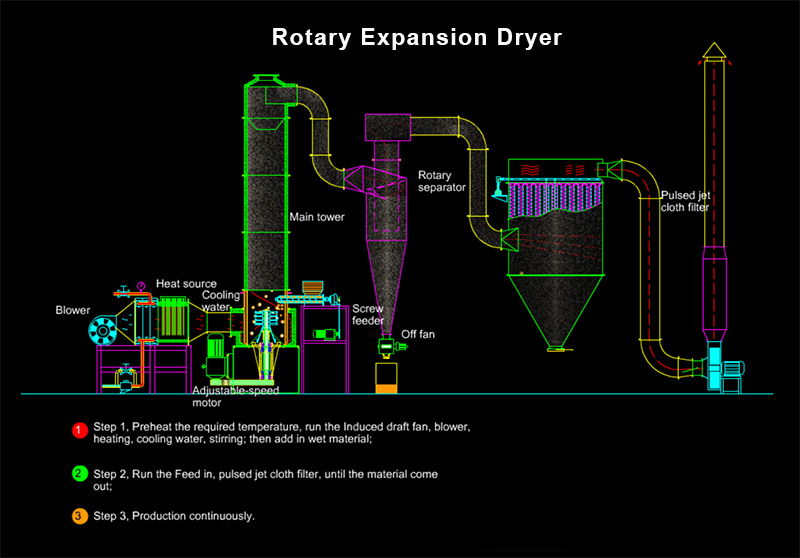

Hot air enters the mixing and crushing drying chamber from the bottom of the dryer at a suitable spraying speed through the inlet pipe, generating strong shear, blowing, and rotating effects on the material. As a result, the material is subjected to centrifugation, shear, collision, and friction, and is atomized, enhancing mass and heat transfer. At the bottom of the dryer, larger and wetter particle clusters are mechanically crushed by the agitator, while particles with lower moisture content and smaller particle size are carried up by the rotating airflow and further dried during the upward process. Due to the rotating flow of gas-solid phases, the inertia of the solid phase is greater than that of the gas phase, and the relative velocity between the solid and gas phases is higher, which enhances mass and heat transfer between the two phases. Therefore, the production intensity of this machine is high.

The working principle of flash drying machine is relatively easy to understand. We can divide the entire drying process into four stages - crushing stage, gas-solid mixing stage, drying stage, and particle size classification stage.

Crushing stage: Crushing is the first and most important step in the entire flash drying process. The dried material is mainly in the form of paste and filter cake. If it is not crushed, flash drying cannot be carried out. Therefore, we can conclude that materials with strong viscosity have poor drying effect when directly using a flash dryer, and appropriate additives need to be added to avoid material agglomeration. The main process is to mix the stirring plate with the high-speed rotating gas to complete the crushing.

Gas solid mixing stage: After crushing, the material is fully in contact with the heating medium in the flash drying main tower. The quality of gas-solid mixing determines the overall drying rate. In order to increase the airflow velocity, an inverted cone structure device is installed at the bottom of the flash dryer.

Drying stage: This process is the process of hot air evaporating material moisture. Unfinished materials fall under the influence of gravity and continue to break and dry; The dried material will move upwards and proceed to the next stage.

Particle size classification: A circular baffle is installed on the upper part of the drying machine, which is called a flash dryer classifier. When the material passes through the classifier, it will be subjected to centrifugal force, showing a spiral upward trend with different rotation radii. Materials with smaller particle sizes are discharged from the inner holes of the classifier; The larger particles of the material are left in the drying chamber for further crushing, and are discharged from the inner hole after reaching the standard particle size.

1. Multiple feeding devices are available for selection, ensuring continuous and stable feeding without bridging during the process.

2. A special cooling device is installed at the bottom of the dryer to prevent material deterioration in the high-temperature zone at the bottom.

3. Special pneumatic sealing device and bearing cooling device effectively extend the service life of the transmission part.

4. The special air distribution device reduces equipment resistance and effectively provides the processing air volume of the dryer.

5. The drying chamber is equipped with grading rings and swirl blades, and the material fineness and final moisture content can be adjusted (such as the final moisture content of calcium carbonate can be adjusted to ≤ 0, 1%).

6. Compared to other drying methods, it can effectively increase the specific gravity of materials.

7. The drying chamber has a high circumferential gas velocity and short material retention time, effectively preventing material sticking to the wall and thermal sensitive material deterioration, achieving high efficiency, speed, small equipment, and large production.

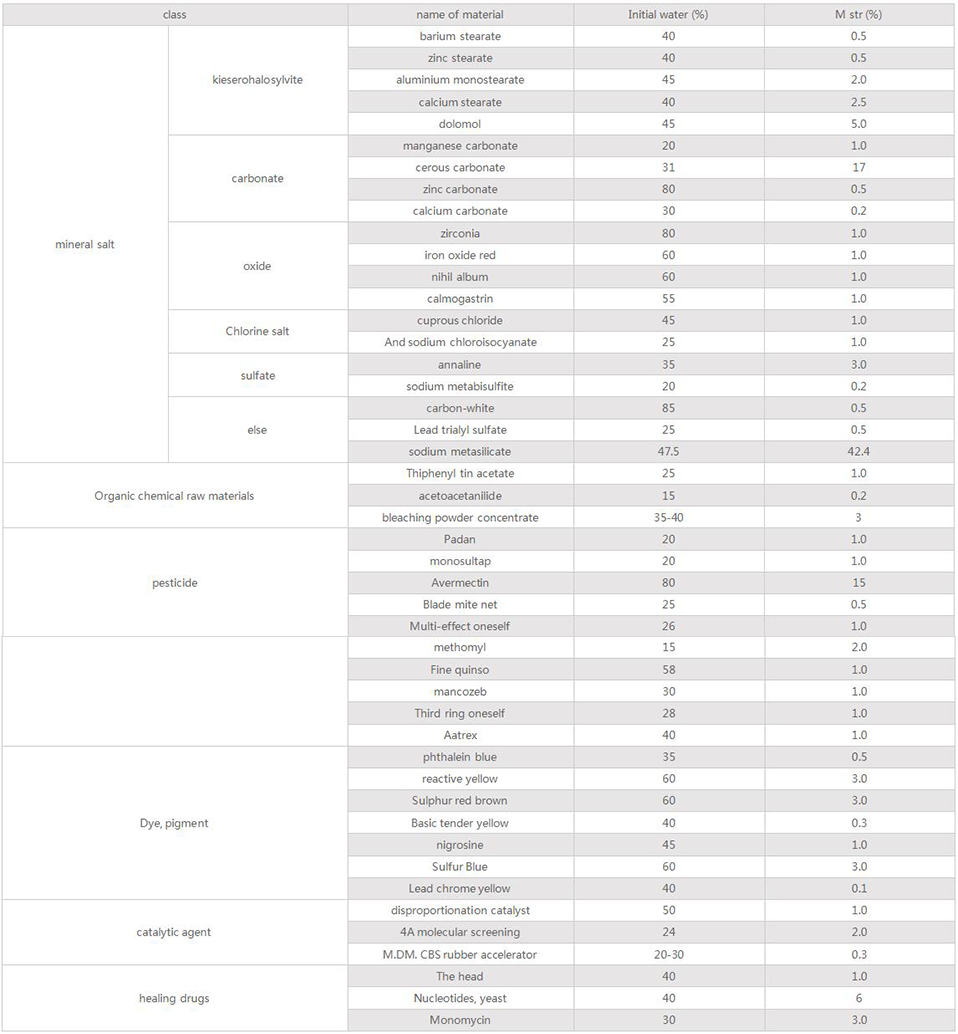

1. Inorganic substances: boric acid, calcium carbonate, hydroxides, copper sulfate, iron oxide, barium carbonate, antimony trioxide, various metal hydroxides, various heavy metal salts, synthetic cryolite, etc.

2. Organic compounds: Atrazine (pesticide insecticide), cadmium laurate, benzoic acid, benzoic acid, fungicide, sodium oxalate, cellulose acetate, etc.

3. Ceramics: kaolin, silica, clay.

4. Dyes: anthraquinone, black iron oxide, indigo pigment, butyric acid, titanium hydroxide, zinc sulfide, various azo dye intermediates.

5. Food category: soy protein, gelatinous starch, distiller's grains, wheat sugar, wheat starch.

Note:

1. The evaporation rate of water is calculated based on an inlet air temperature of 200 ℃ and an outlet air temperature of 80 ℃;

2. The installed capacity is the basic data and can be changed according to the physical and chemical properties of the material;

3. The land area is arranged according to the actual situation, and the data in the table is for reference only.